APQP4Wind: How to reduce costs using Advanced Product Quality Planning

Learn how applying this methodology, which optimizes quality and reduces costs, can improve processes and prevent rework.

Why standardized quality planning is key: Lessons from homebuilding & APQP4Wind

Imagine you are building a house without consulting the future resident about their needs, such as size, quality, finishing sophistication, location, accessibility, and legal requirements.

Now, picture the suppliers of materials and components for this house also neglecting to gather the same crucial information regarding the resident’s choices.

Next, imagine you aim to deliver a high-quality product to your customer, but you must first correct every single dissatisfaction before handing over the keys.

Lastly, consider that this potential buyer is torn between purchasing the house you are constructing and two other options.

The three approaches to quality planning

Option 1: The traditional approach

The first approach lacks structured quality planning. Corrections and adjustments are made after the house is already built, leading to delays, rework, and increased costs.

Option 2: The proprietary quality planning approach

In the second option, the builder follows an exclusive quality planning method. A thorough process is followed to gather customer requirements, which are then translated into product and service specifications. Every material and component must undergo an approval process according to this proprietary method before being purchased, manufactured, and delivered. The house is handed over only after all requirements are met.

Option 3: The standardized market approach

In the third approach, the builder adopts a standardized market-based product quality planning framework. The steps for gathering customer requirements are well-established, and the criteria are industry-standard. The research process is streamlined and efficient. Suppliers follow the same standardized quality planning process, allowing for pre-approved materials and components available in the market. The builder can simply compare prices and procure the best options. The house is delivered only after all requirements are met.

It is easy to see that the third option is likely to be the most cost-effective and fastest. In construction, delivering sooner also means reducing costs.

The value of a standardized Advanced Product Quality Planning (APQP) approach

This illustrates the first and most significant benefit of a standardized market-based Advanced Product Quality Planning (APQP) approach—delivering quality products at the lowest possible cost of quality. By making this method a market standard, materials and components are more likely to meet user requirements without the need for extensive requirement gathering, breakdown, and validation processes. Price competition becomes meaningful, and lead times are significantly reduced.

APQP4Wind: A standardized framework for wind energy

APQP4Wind provides a structured and standardized process framework designed to gather and translate customer and user requirements into specialized product and process requirements for the wind energy market. This spans from defining the quality program to validating the product and production process.

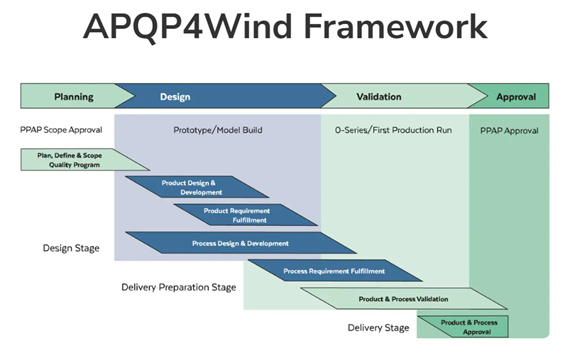

This framework represents the timeline and stages of product and process development:

- By following the elements of each phase, customer needs are identified in the initial stage and then translated into product and process requirements in the subsequent phases.

- While the phases are not strictly dependent on each other, ensuring all deliverables are met guarantees that each step is completed in due time, avoiding uncertainty in the final approval phase.

- This process minimizes waste and rework, ensuring efficiency.

Tools and benefits of APQP4Wind

This structured framework is supported by analytical tools and product and process approval parameters, assisting development teams in making the entire program faster and more precise.

In a business landscape where Time to Market (TTM) is increasingly compressed, and companies must develop more products in less time for diverse customers, adopting a standardized market approach simplifies the execution of multiple programs simultaneously.

Just like in the house-building analogy, developing products based on APQP4Wind ensures products are more aligned with customer needs, delivered faster, and at reduced costs.

APQP4Wind’s industry-wide adoption

The APQP4Wind framework is endorsed by key industry players, including turbine manufacturers, component suppliers, and energy producers. These stakeholders rely on this standard across the supply chain to facilitate price comparisons and cost reductions. All major turbine manufacturers have adopted APQP4Wind, solidifying it as a market standard.

Cost reduction: A key factor for business sustainability

In times of market downturns, cost reduction is essential for business sustainability. It is up to us to understand and leverage APQP4Wind to optimize costs and efficiency.

Contact us now to join our APQP4Wind training programs and become an expert in this standard, its application, and its benefits!

- APQP4Wind Management Awareness Training: www.dnv.us/training/apqp4wind-management-awareness-138767

- APQP4Wind Specialist Training: www.dnv.us/training/apqp4wind-specialist-138770

About the Author

Irineu Costa

Graduated in Production Processes from FATEC-SP, with an MBA from FIA and a Master's in Production Engineering from ITA. Since 2001, he has led new product implementation projects with experience in the automotive and aerospace industries (Embraer) and, since 2007, in the wind energy sector as a project manager. With over 30 production line implementation projects for wind turbine blades, he advocates for a unified Product Quality Planning standard, such as APQP4Wind, to reduce costs, implementation time, and quality risks.

3/4/2025 2:00:00 PM